Home / Heaters / Band Heaters / Mica Band

Mica Band Heater Phoenix Thermal Supply

Mica Band Heaters

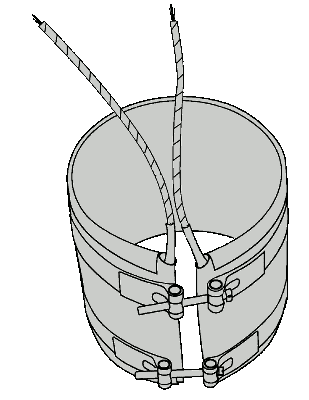

Phoenix Thermal Supply has the best quality Mica Band Heaters. We have Stock, Same Day Rush, or Custom Made 1, 3, 5, and 10 day deliveries available. Quick Ship Extruder Barrel Band Heaters, Nozzle and Cylinder Pipe Heaters. Industry first technology with ultra high temp best mica insulation. PTSHEAT has top quality Mica Band heaters!

Phoenix Thermal Supply, your mica band heater supplier, has extensive stock on popular Mica Band Heaters. We supply any design imaginable from Simple Nozzle Heaters to Multi-Piece designs with holes and notches.

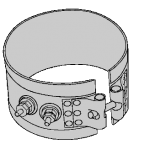

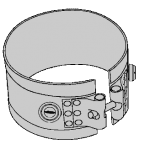

Our engineers can duplicate your (OEM) Original Equipment heaters to provide same Form, Fit, and Function Band Heaters. Our Best Mica Band heaters have Only the highest quality materials that are used for optimal performance. Options for mica band heaters One-Piece Band, Two-Piece Band, One Piece Expandable, Holes & Cut-Outs Hinged Two-Piece, and Thermocouple Options, Lead options, Post Terminal, Barrel nut lock option on both one and two piece, Spring Clamp lock option, Flange lock option both one and two piece, and Standard Strap Clamps. Other options include Terminal Box, Euro plug, and Box style Band Heaters.

Mica band heaters support up to 900 degrees F. Call or e-mail our engineers to discuss your needs today. If we don’t have your heater in stock, we have 1 day, 3 day, and 5 day rush available for quick shipping on custom designs. 10 days on manufactured standard lead-time. Phoenix Thermal Supply is your trusted heater band supplier for Mica Band Heaters. Ask about our Local stocking options… No Problem- We hold stock for our valued customers!!

Our heater best mica bands suppliers have local stock and factory stock of several designs of mica band heaters ready to ship!! If one of the stock units will not work for you, we can supply an assembly stock unit to cover your application needs in 1, 3, 5, or 10 days. Custom- Made-to-Order units are available to ship in 1-3 weeks.

Find out how we can help, contact us today!

Need Custom Mica Band Heaters Fast?!!

Our Mica Band Expedite Options are Always Available on Custom Products! Call or email one of our Sales Engineers. We also have plenty of expedite options available for cartridge heaters, silicone rubber heaters, and thermocouples as well!!

Here is more good news about PTSHEAT:

We accept orders regardless of quantity or dollar amount.

We accept blanket orders with tentative ship dates up to 1-year from order date.

We offer different expedite options for most product lines.

We stock thousands of replacement heaters in standard configurations.

We are committed to our standard lead time of 9 working days, not weeks!

Please see the pictures and descriptions below for all the options:

Mica Band with Lead wire only terminations (standard fiberglass lead wire is 550°C Duraflex wire)

L1 Fiberglass Leads

L2 Fiberglass Leads

L3 Fiberglass Leads

L4 Fiberglass Leads

L5 Fiberglass Leads

L6 Fiberglass Leads

Type L1 leads: Fiberglass protected leads exiting both sides of gap are standard unless otherwise specified.

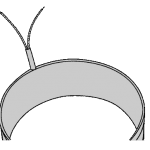

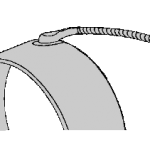

Type L2 leads: Fiberglass protected leads exiting thickness of band at 180° from the gap unless otherwise specified.

Type L3 leads: Fiberglass protected leads exiting straight out the side are available on any construction.

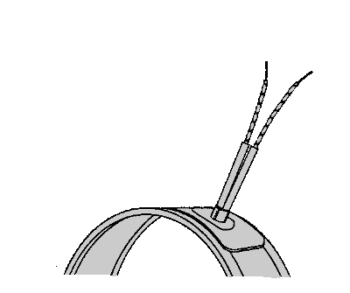

Type L4 leads: Fiberglass protected leads exit at 90′ from lead cap located at any position on the heater’s top metal.

Type L5 leads: Fiberglass protected lead wires on one side of gap are available on any construction.

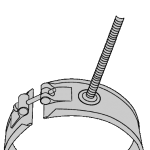

Type L6 leads: Fiberglass protected leads with Stainless steel spring provides extra support, protecting leads from sharp bends.

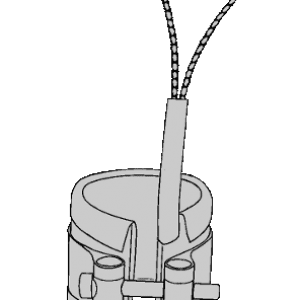

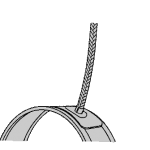

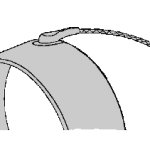

Mica Band with STAINLESS STEEL BRAID PROTECTION over Lead wire terminations (standard fiberglass lead wire is 550°C Duraflex wire)

B1 Braided Leads

B2 Braided Leads

B3 Braided Leads

B4 Braided Leads

B5 Braided Leads

B6 Braided Leads

Mica Band with Stainless Steel Protection over standard fiberglass lead wire is 550°C Duraflex wire

Type B1 braid: Stainless Steel braid over Fiberglass exiting both sides of gap.

Type B2 braid: Stainless Steel braid over Fiberglass exiting 180 degrees from gap unless otherwise specified.

Type B3 braid: Stainless Steel braid over Fiberglass straight out side are available on any construction.

Type B4 braid: Stainless Steel braid over Fiberglass with right angle exit through cap located at any position on top metal.

Type B5 braid: Stainless Steel braid over Fiberglass lead wires on one side of gap are available on any construction.

Type B6 braid: Stainless Steel braid over Fiberglass lead wires with stainless steel spring guard for flex bend protection.

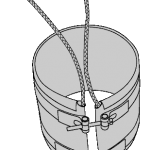

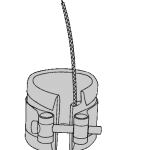

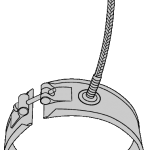

Mica Band with STAINLESS STEEL HOSE / CONDUIT PROTECTION over Lead wire terminations (standard fiberglass lead wire is 550°C Duraflex wire)

C3 Hose Leads

C4 Hose Leads

Mica Band with Stainless Steel Flexible Conduit over fiberglass lead wire

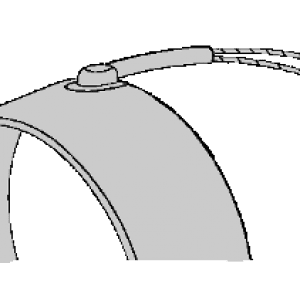

Type C3 conduit: Flexible Stainless Steel Conduit over Fiberglass offers utmost lead abrasion protection from top metal.

Type C4 conduit: Flexible Stainless Steel Conduit over Fiberglass exiting through right angle cap located at any position.

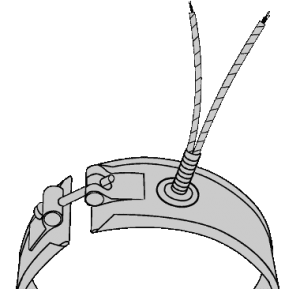

Mica Band with POST TERMINAL OR EURO CUP AND BOX terminations (standard fiberglass lead wire is 550°C Duraflex wire)

N1 Post Terminals

N2 Post Terminals

N3 Post Terminals

BN Button Terminals

Vertical Euro Plug

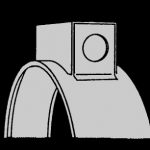

Terminal Box

Mica Band with Post terminals (All post terminals are a 10-32 thread)

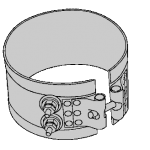

Type N1 terminals Post Terminals side by side on one side of gap. This is standard position for heaters 2” wide and greater.

Type N2 terminals Post Terminals on each side of gap. Standard position for nozzle heaters and band heaters less than 2” wide.

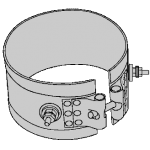

Type N3 terminals Post Terminals In-Line on one side of Gap.

Type BN terminals Button terminals may be ordered in same position as N-1, N-2 or N-3.

European Plug Vertical directly mounted to top metal of band heater.

Terminal Box over post terminals.

Standard Specification and Tolerances

Performance Ratings

Maximum Temperature:

Standard Sheath: 482°C (900°F)

Nominal Watt Density: 3 to 7 Watt/cm² (20 to 45 Watt/in²)

Maximum Watt Density: Dependent on heater size and operating temperature

Electrical Ratings

Maximum Voltage: 480 Vac

Dual Voltage or 3-Phase: Available depending on heater design

Maximum Amperage:

Lead Wire Termination: 10 Amp

Screw Terminations: 8-32 UNF—20 Amp; 10-32 UNF—25 Amp

Resistance Tolerance: 10%, -5%

Wattage Tolerance: 5%, -10%

Physical Size Construction Limitations

Minimum Width: 19.1 mm (3/4″)

Width Tolerance: 1.59 mm (±1/16″)

Minimum Inside Diameter: 22.1 mm (7/8″)

Nominal Gap: 9.5 mm (3/8″)—if a larger gap is required for probes or thermocouples, specify when ordering

Built-In Brackets

Heater Width

38 to 76 mm (1½ to 3″) Number of Brackets 1

79 to 127 mm (3 1/8 to 5″) Number of Brackets 2

130 to 145 mm (5 1/8 to 67/8″) Number of Brackets 3

178 to 254 mm (7 to 10″) Number of Brackets 4

257 to 381 mm (10 1/8 to 15″) Number of Brackets 5

If tighter tolerances are required, contact PTSHEAT: https://phoenixthermalsupply.com/contact-us/.

Mica Band Installation Instructions:

- Mica Band Heaters should be installed on smooth clean cylinders or flat surfaces.

- When putting Mica Band Heaters on barrel or nozzle, do not open the heater for installation. This can damage the mica and cause premature failure.

- Make sure the Mica Band Heater is seated properly and the clamping band tightened as much as possible.

Optimizing Heater Performance

- Use the correct Mica Band Heater diameter on the application to ensure proper fit.

- Retighten Mica Heater clamps after being energized and cooled.

- Avoid excessive torque on post terminals. Use a wrench to hold the bottom nut while loosening/tightening the top nut. 20 In-lb max torque on post terminal nuts.

- Do not allow contaminants such as dirt, oil and plastics to collect on Mica Heaters. These materials can carbonize and cause electrical shorts.

- Avoid moisture and splash down areas. Moisture could be wicked up by the leads or get into the inside of the heater causing the heater to fail.

- Max Pressure for Mica Strip Heaters is 150 PSI.

DO YOU HAVE AN EXISTING MICA BAND DESIGN?

Allow our sales engineers to duplicate or trouble shoot and redesign your heaters as needed. We are trained and skilled to give you the exact form, fit, function heater that you need. We can crossover or supply the same heater with a OEM part number, Manufacturer part number, and a good set of pictures and measurements where needed. We can walk you through the process and work up a quote in minutes. Give us a call, text or email today!

Mica Band Applications:

- Plastic Injection Molding Machines

- Plastic Extrusion Machines

- Blown Film Dies

- Extrusion Dies and Cross Heads

- Blow Molding Machines

- Hot Runner Molds

- Oil Reclamation Equipment

- Food and Candy Extruders

- Drum Heating

- Holding Tanks

- Vending Machines

- Food Service Warming

- Autoclaves & Sterilizers

- Metallurgical Analyzers

- Fluidized Beds

- Pulp and Paper Processing Equipment