Home / Heaters / Tubular Heaters / Milled Groove Tubular Heaters

Milled Groove Tubular Heaters

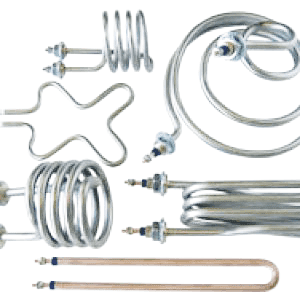

Flexible Tubular Heaters

Photo title

Tubular milled groove heaters are precision-formed and customized to your hot runner mold application. Even tight radius bends of 0.250 inch maintaining tolerances of ±0.062 to ±0.002 inch are possible. This capability not only allows you freedom to design for the optimum uniform heating pattern for your plastics process, but also guarantees quick and easy installation.

Simply send your groove dimensions in a detailed drawing or on CAD file. Depending on the formation requirements, the resulting CAD design will be transferred to our factory CNC bending equipment and a highly skilled bending operator.

A variety of sheath materials are available including alloy 800, 304 stainless steel and 316 stainless steel, each offering unique advantages of long life in high temperature molds, rigidity to maintain shape during shipment and corrosion resistance.

PTSHEAT not only delivers the heat fast to the process with efficient heat transfer, but guarantees the heater’s fast delivery, too. While Phoenix guarantees standard delivery within three to four weeks, tough delivery schedules are our specialty.

If you do not have a CAD drawing, we can work with one of our Flexible Tubular Heaters. They can be easily hammered into your hot runner equipment. The flexibility of our stock will allow several options for a quicker shipment than one of our formed rigid sheath heaters. Our engineers will help you select the best option for your parts needs.

Milled Groove Applications:

Hot Runner Manifold Heating