Home / Heaters / Strip Heaters / Mica Strip

Mica Strip Heaters Phoenix Thermal Supply

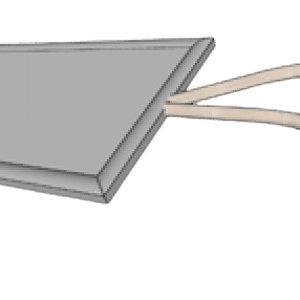

SL1 Leads

SL2 Leads

SL3 Leads

SL4 Leads

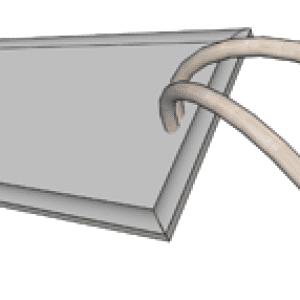

SB1 Braided Leads

SB2 Braided Leads

SB3 Braided Leads

SB4 Braided Leads

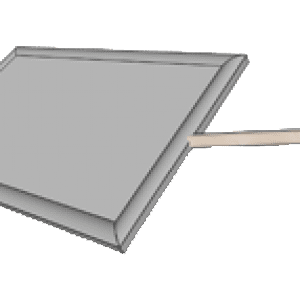

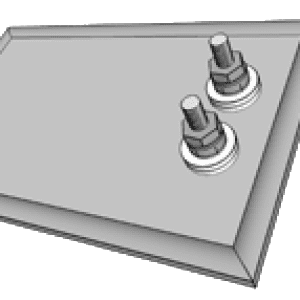

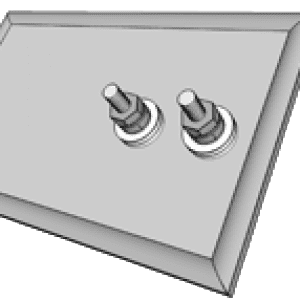

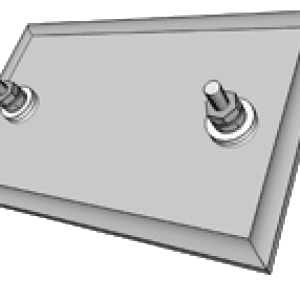

SN1 Terminals

SN2 Terminals

SN3 Terminals

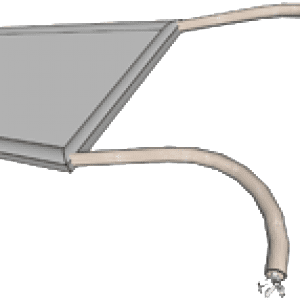

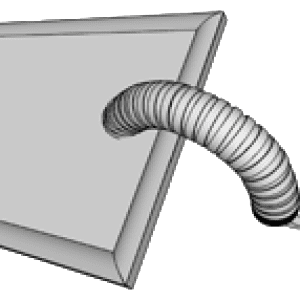

SC3 Hose Leads

Phoenix Thermal Supply Mica Strip Heaters are designed for Industrial electric equipment, process machinery, extruder die heaters, molding industrial electrical equipment and these heater strips can be designed and terminated in a variety of ways including leads and post terminals. Phoenix Thermal Supply mica strip heaters are an excellent quality industrial electric heater!

All of our Mica Strip Heaters feature a high temperature oxidation metal sheath and high grade mica insulation resistant to moisture and high temperatures. Nickel/Chromium resistance wire evenly wound provides for uniform and reliable heat distribution. PTSHEAT heaters are LLL recognized to standard UL499 and test to Canadian Standard C222.

C222 Fil

All configurations can be supplied in different sizes & with or without protection.

Special Construction Options for Mica Strip Heaters

These are a few custom options available for mica band heaters. Phoenix Thermal Supply custom designs band heaters:

Stainless Steel Sheath – is recommended and used for applications where temperatures are over 700’F.

Odd Constructions – are available for easy installation. If you can draw it, we can design it with and without mounting holes.

Custom Holes and Slots – are designed for applications in odd locations needing heat. For sensor holes or die locations and fit.

Flat Construction – Narrow 1″ and 1-1/2″ heaters are designed for easy installation quick installation for any application.

Box or Rectangular Construction – 2pc L-shaped square heater constructions.

Flat Construction with Special Backer Plate – Excellent Clamping Method to keep your heater from flexing under temperature.

Mica Strip Heaters are easily designed to fit ANY application.

Cone Heaters – Mica Strip Heaters can be cut and curved to fit Cone Shaped and Tapered Parts.

EuroPlug Connections – This style of electrical connection is popular for quick connect and disconnect of power at the heater

Butt-Folded Top Metal – This allows even thickness across the full width of the heater. popular in-between plates and presses.

Easily Customizable – Mica Strip heaters can be formed flat, curved, round, square, or in any geometrical shape.

Ring Heaters – Popular Configuration for hard to heat parts, pumps, etc.

Terminal Box over post terminals – To cover post terminals and electrical connections at the heater.

Proper Mica Strip Heater Installation Instructions:

- Mica Strip Heaters should be installed on smooth clean cylinders or flat surfaces.

- When putting Mica Heaters on block or surface, do not curve, fold, or open the heater for installation. This can damage the mica and cause premature failure.

- Make sure the Mica Strip Heater is seated properly and secured against the heated surface as tight as possible.

Optimizing Heater Performance

- Use the correct Mica Strip Heater length and width on the application to ensure proper fit. These heaters need proper conductivity to evacuate the internal heat.

- Retighten Mica Strip Heater clamps after being energized and cooled.

- Avoid excessive torque on post terminals. Use a wrench to hold the bottom nut while loosening/tightening the top nut. 20 In-lb max torque on post terminal nuts.

- Do not allow contaminants such as dirt, oil and plastics to collect on Mica Strip Heaters. These materials can carbonize and cause electrical shorts.

- Avoid moisture and splash down areas. Moisture could be wicked up by the leads or get into the inside of the heater causing the heater to fail.

- Max Pressure for Mica Strip Heaters is 150 PSI.