Pressure Sensors

Home / Sensors / Pressure Sensors

Pressure Sensors

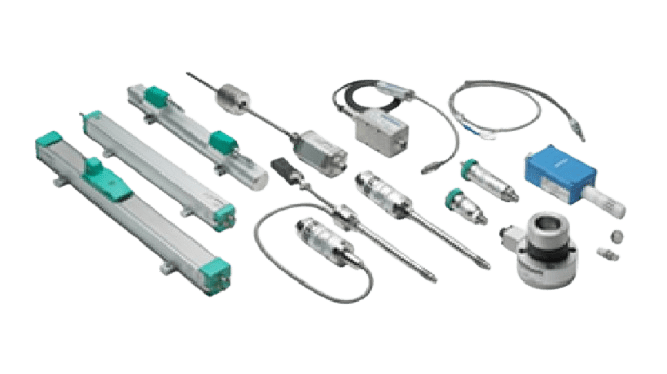

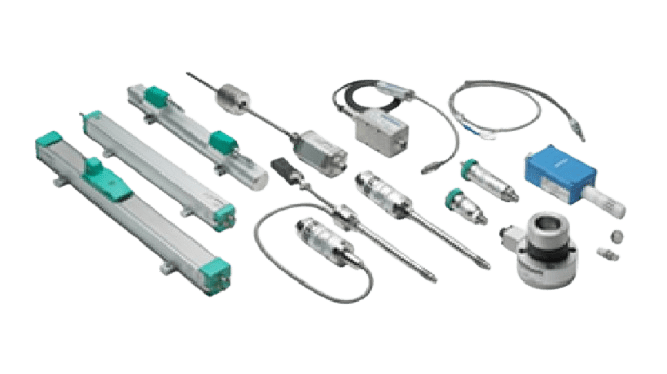

Pressure Transducers, Pressure Transmitters, Linear Transducers, Process and instrument measurement, Dynisco, Gefran, Gentran, MPI, GP-50

Melt Pressure Transducers convert melt pressure into an electrical readout signal.

Gefran M3 Melt pressure transducers the mercury-filled melt pressure sensors, designed by Gefran on an extensometric technology, are suitable to work at high temperature, up to 400°C, assuring a total compliance with the maximum levels of accuracy and of reliability. These pressure sensors output at mV / V output. Theses sensors are also a drop in replacements for other brands. Give us a call for a quote.

- Pressure ranges from: 0-35 to 0-2000 bar / 0-500 to 0-30000 psi

- Strain gage Wheatstone bridge

- Accuracy : <±0.25% FSO (H); <±0.5% FSO (M)

- Internally generated 80% calibration signal (R-Cal)

- Fluid-filled system for temperature stability

- Fully interchangeable with all existing brands

- Grade of protection: IP65 (6-pin connector version)

- 1/2-20 UNF, M18x1.5 standard threads; other types available on request

- Standard diaphragm is 15-5 PH stainless steel with GTP coating

- 17-7 PH corrugated diaphragm with GTP coating for ranges below 100 bar-1500 ps

- Other diaphragms available on request

Phoenix Thermal Supply stocks several configuration options. Our sales representatives can help you determine which Melt Pressure Transducer will best fit your application requirements. Contact us

Types of Melt Pressure Tranducers

- Rigid stem configuration for fast, easy installation

- Flexible configuration for applications requiring further thermal isolation or where installation would be otherwise difficult or impractical

- Pressure/temperature configuration requires only one mounting hole for the measurement of both process values

- Exposed capillary configuration fits in space-restricted locations

Melt Pressure Transducer configurations also available as

- Oil-filled tranducers

- Explosion proof transducers

- explosion Proof Sensors

- Alloy-filled

- Mercury filled

Industrial Pressure Transducers

Industrial Pressure Transducers measure fluid, liquid, or gas pressure in industrial applications.

Pressure Transducers, Pressure Transmitters, Linear Transducers, Process and instrument measurement, Dynisco, Gefran, Gentran, MPI, GP-50

![]() What is a good Pressure Transducer Application?

What is a good Pressure Transducer Application?

It is used for the control of the extrusion process of clean materials such as sheets, composite materials, films, pipes, food packaging, medical packaging, etc.

Product features

Remotely autozero and locally magnetic zero

80% Internal calibration

Mercury free filling and relay output is optional

- We also offer alloy filled eco-friendly options

![]() Pressure Transducer Technical data

Pressure Transducer Technical data

Electrical connection & Debugging

After the pressure sensor has been installed on the pipeline, the electrical connection must be carried out in accordance with the connection mode shown in the wiring diagram below.

MPT series is equipped with an integrated amplifier circuit. The calibration process must be that the pipeline is heated, and the pressure is zero. The zero point is adjusted by activating the autozero function, which is via shorting two pins to start (refer to the diagram below) or magnetic pen. Then 80% of the output signal is detected (see wiring diagram), and the pressure sensor will provide a standard 80% measured value signal.

Rezero with Magnetic pen

3.33mV/V Output (4-wire) 6-pin connector

| PIN | Function | Wire Color |

| A | Signal+ | Red |

| B | Signal- | Black |

| C | Power+ | White |

| D | Power- | Green |

| E | 80%+ | Blue |

| F | 80%- | Orange |

4…20mA Output (2-wire) 6-pin connector

| PIN | Function | Wire Color |

| A | Power+ | Red |

| B | Power- | Block |

| C | White | |

| D | Shorting D&F to rezero+ | Green |

| E | 80%+ | Blue |

| F | Shorting D&F to rezero+/80%- | Orange |

0…5V / 0…10V (4-wire) 6-pin connector

| PIN | Function | Wire Color |

| A | Signal+ | Red |

| B | Signal- | Block |

| C | Power+ | White |

| D | Power- / 80%- / Shorting D&F to rezero- | Green |

| E | 80%+ | Blue |

| F | Shorting D&F to rezero+ | Orange |

*B and D pins are connected internally

It must be a shielded cable, each core wire is about 0.3mm2, the heat-resistant temperature is not less than 105℃, each core wire connection terminal should be insulated and protected by heat shrinkable tube, the shielding wire should be connected with the plug-in metal, and the cable should be specially welded carefully, otherwise it may cause signal transmission errors or damage the product. It is recommended to use a dedicated cable that has been soldered by PTSHEAT. For extra wires in the cable, each wire needs to be individually wrapped with insulating tape.

Pressure Transducer Installation

When installing the pressure sensor, the sensor hole should be within the size requirement marked in following drawing and the assembly accuracy can be checked by testing bolts. Before installing the sensor, first clean the impurities in the hole and between the threads, then the thread of the sensor is coated with heat-resistant slurry, the screw teeth can be avoided.

The installation force is very important, the installation torque of the sensor can only act on the shaft (hexagon), do not apply any force to the head of the sensor. The housing should be kept away from high temperature areas.

1/2-20 UNF /M14×1.5= Maximum starting torque: 40Nm M18 x 1.5 = Maximum starting torque: 50 Nm

Proper Pressure Transducer Removal

The removal of the sensor must be done under heated conditions (plastic melting point). When remove the sensor, please note that the diaphragm has no contact pressure. The force to remove the sensor must only be applied on the shaft (hexagon), and do not apply any force to the head of the sensor.

![]() Pressure Transducer cleaning

Pressure Transducer cleaning

To clean the diaphragm, the sealing surface and thread of the sensor must have the same temperature as the melting point of the plastic. Both the diaphragm and the sealing surface can be wiped clean with soft cloth, and the thread can be cleaned with a steel brush or a copper brush.

(Do not touch the surface of the diaphragm with the steel brush.)

![]() Pressure Transducer Transport and storage

Pressure Transducer Transport and storage

MPT series is usually packaged separately. The front thread of the rigid stem and the diaphragm is protected by a protective cap. This protective cap should be tightened at any time during storage, and only opened during installation.

Note PTSHEAT also supplies: Mounting brackets, extension cables, connectors, cleaning kits, drill kits, dummy plug etc. accessories, please contact [email protected]

Pressure Transducer Applications:

- Plastics Extrusion

- Rubber Extrusion

- Polymer Processing

- Vacuum Equipment

- Liquid Pressure Measurement

- Oil & Gas

- Food Industry

- Pharmaceutical Industry

- Process Industry

Search

Products

- Heaters

- Sensors

- Power Controls

- Temperature and Process Controllers

- Accessories for Industrial Thermal Process

PTSHEAT Sensors

RTD’sPressure SensorsInfrared SensorsThermocouples