Home / Heaters / Cartridge Heaters / Standard Sheath

EXACT WATLOW FIREROD CROSS-OVERS SHIPPED FAST!!!

The most popular product is our Cartridge heater. Our construction and quality is the Best in the industry. We make low to medium and high watt density Cartridge heaters.

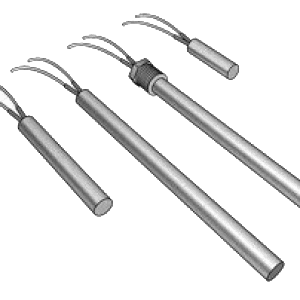

Here are some popular Cartridge Heater Designs

Search

Cartridge Heaters

We have local stock and factory stock of several designs of cartridge heaters ready to ship!! If one of the stock units will not work for you, we can supply an assembly stock unit to cover your application needs in 1, 3, 5, or 10 days. Custom- Made-to-Order units are available to ship in 1-3 weeks.

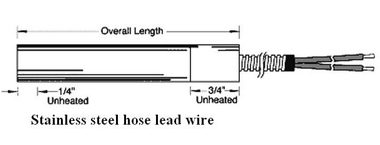

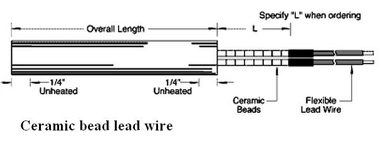

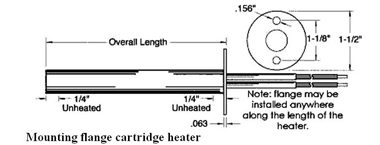

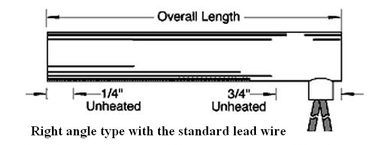

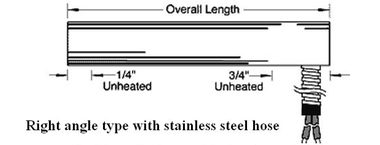

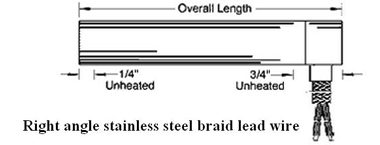

Our Cartridge Heaters can be inserted into drilled holes to heat metal parts. They come in standard round split sheath round, or square shapes and a wide variety of sizes of industrial heaters, with several lead styles that are able to withstand constant flexing, and corrosive or moist environments. Watlow Cartridge and Tempco.

PTS, Phoenix Thermal Supply can assist you in determining the right diameter and length along with the wattage and voltage for your cartridge heater requirements. We have many different sizes in stock for immediate shipment.

Stock or made-to-order, the HOTROD & FIREROD delivers heat in a hurry. More than 250,000 FIREROD & HOTROD cartridge heater designs are available.

Phoenix Thermal Supply offers many delivery programs to meet your needs: same day shipment, Ship-to-Stock or custom as needed. CUSTOM HEATERS RUSH AVAILABLE: 1 DAY, 3 DAY, 5 DAY, OR STANDARD 10 DAYS.

PTSHEAT Designs and supplies a variety of cartridge heaters. We have all construction types to fit your application needs. Choosing the right design is important for heater life and production requirements. Call our technical sales to help you select the right heater for your application.

- Bent Cartridge Heaters This style is used in tight fit areas. Heated and non-heated zones can vary on either side of the bend. Bends need to be made in the un-heated section. Very popular in packaging and labeling equipment. Heater Diameter: 1/4″ Minimum Bend Radius: 1/2″, Heater Diameter: 5/16″ Minimum Bend Radius: 1/2″, Heater Diameter: 3/8″ Minimum Bend Radius: 1/2″, Heater Diameter: 1/2″ Minimum Bend Radius: 3/4″, Heater Diameter: 5/8″ Minimum Bend Radius: 1″, Heater Diameter: 3-4″ Minimum Bend Radius: 1-1/4″

- Double Ended Construction This style is used in areas where electrical wiring is not brought in on both ends of a machine. Available with screw terminals, pins, and leads.

- Multi Zone and Distributed Wattage Used For better heat control and temperature tolerances. This construction covers heat losses on packaging machinery and molds. Individually controlled heating zones.? As many as 5 zones in 3/4″ and 1″ diameter heaters and 3 zones in other diameters. Leads are color coded for easy identification.

A Phoenix Thermal Supply Cartridge Heater can be used in a variety of applications!

Your cartridge heater’s life can be extended if properly designed for the application. Please contact one of our sales engineers to discuss your current design and we can work with you to verify if the watt density, sheath, form, fit, function is proper. Our experience is your advantage!

Technical Details:

1. Tube diameter: Φ3mm-Φ30mm

2. Tube material: SS304, SS316, SS321, SUS310S, NICOLOY800, etc.

3. Insulation Material: High-purity Mgo

4. Resistance wire element: Ni-Cr or Fe-Cr-Al

5. Wattage density: high/middle/low (5-25w/cm2)

6. Lead connection option: Crimped or Swaged leads

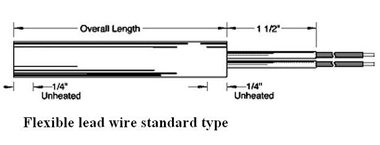

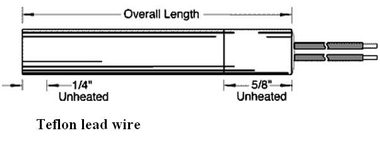

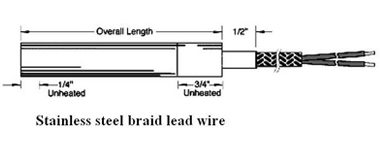

7. Lead wire type: 10″ Standard (Teflon/silicone/high temperature fiberglass

Applications:

1. Liquid Immersion

2. Plastic Molds

3. Dies

4. Labeling

5. Medical Equipment

6. Platens

7. Packaging Equipment

8. Hot Stamping

9. Sealing

10. Injection Molding

A PTSHEAT Cartridge heater provides localized heat to restricted work areas requiring close thermal control. Dies, platens and a variety of other types of processing equipment are efficiently heated. Closely controlled work temperatures up to 1400° F (760 C) are obtained by a combination of heater location and proper wattage output.

PTSHEAT can provide you with heating element manufactured to your specifications to accommodate your application. Phoenix Thermal Supply can take care of your order needs! We will walk you through specifying the wattage, voltage, diameter, length, lead length, and lead type. This product will be readily and quickly shipped from our stock or rushed to order.

How is a Cartridge Heater made & Why do they fail!

Are your heaters failing prematurely? The useful life of a cartridge heating element is determined by how quickly the heat generated in the resistance wire can be dissipated to the outside sheath. To accomplish a useful life of the heater, two methods of manufacturing cartridge heaters are available; STANDARD cartridge heaters and SWAGED cartridge heaters. Although both type heaters look identical, the internal construction is very different.

How is a Cartridge heater made?

STANDARD CARTRIDGE HEATER

Nichrome wire heating coils are inserted in holes formed in ceramic tubes. Pure magnesium oxide filler is vibrated into the holes housing the heating coils to allow maximum heat transfer to the stainless steel sheath. The heater then has a heliarc welded end cap inserted on the bottom of the heater and insulated leads are installed. Original old standby made with ceramic supported wire insertion into a metal tube filled with loose fill inorganic ceramic powder (usually magnesium oxide). Cross sections can be round from 1/8 inch diameter to 2 inches diameter; square, hexagon, triangular, etc. Cross sections are also available; length can be from < 1 inch to > 4 feet. This is usually the first choice consideration for OEM’s and accounts for an estimated 20% of total electric heaters made. Power density is < 100 watts per square inch and temperature up to 1200 degrees F are possible.

SWAGED CARTRIDGE HEATERS

Nichrome wire is wound around a ceramic core which situates it in close proximity to the heater sheath. Pure magnesium oxide (MGO) is then vibrated in and the heater is swaged to a specific diameter. This compresses the MGO so it becomes an improved conductor of heat from the wire while maintaining its dielectric properties. Developed about 60 years ago, possible influenced by the good power density capacity of roll compacted tubular, said units by nature of compacting the inorganic power tightly to the resistance wire makes an excellent unit. Compared to NON-SWAGED units, power density is capable of being increased (< 500 watts per square inch) and temperatures can approach 1800 degrees F. The requirement for higher quality tubing (to withstand rolling/swaging compaction), precision fired crushable ceramic internal parts plus the added compaction operation make this unit 1 ½ – 3 times standard cartridge cost. They are available in diameters from 1/8 inch to 1 inch and length from 1 inch to > 3 feet. A first choice for OEM’s that need high power density/temp. inside a small envelope

Bottom Line: Swagging a cartridge improves the heat transfer rate and allows for higher watt densities to be used on swaged cartridge heaters. Swaged heaters can operate at higher temperature and vibration applications with trouble free service.

Everyone asks “Why does a Cartridge heater fail”?

1. IMPROPER FIT!

The most common cause of cartridge heater failure is an improper fit in the hole into which it is inserted. If the heater cannot dissipate the heat being generated and produced by contact with the sheath, the temperature inside the heater will continue to rise until the heater fails. We can help you calculate the best hole size based on your process temperature and your heaters watt density.

2. MOISTURE and/or IMPURITIES ARE PRESENT!

The MGO used in cartridge heaters is hydroscopic. Every time power to electric heaters is eliminated, an internal vacuum occurs which draws in air from the surrounding area. If moisture or impurities (oil, gas, etc.) are present, they can be drawn in to the heater, and cause a short circuit resulting in a heater failure. We can help you select the best end seal for your area of installation.

3. WATT DENSITY IS TOO HIGH!

If the watts/square inch is excessive, the heater will not be able to dissipate the heat and the heater will fail.

4. INCORRECT VOLTAGE!

The wattage of any electric heater varies as the square of the voltage. If a 120 Volt heater is powered on 240 Volts, the wattage will be 4 times greater than that for the same 120 Volt heater. Under normal conditions, this may result in heater failure.

We have cartridge heaters, round, square , and rectangular from 1/8” to 2 3/8” diameter and metric sizes from 6mm to 20mm. We have special features for lead configuration and protection, end seals for adverse environmental situations, and sheath materials from stainless steel to titanium.

We can evaluate any failed heater to determine the cause of failure!

Obtaining maximum heat transfer and long life for high watt density heaters.

Fit

Proper hole fit is important for heat transfer. High watt density heaters require careful fit to insure optimum performance and long life. PTSHEAT recommends that installation holes not be drilled and reamed over .002 larger than the nominal hole size required. The heaters are sized so that they never exceed .005 less than the nominal diameter and always at least .001 under the nominal diameter for a slide fit. These close fits insure rapid heat transfer from the heater and also help keep the unit as cool as possible, which contributes to long life.

Cycling

Rapid cycling of heaters from very low to very high temperatures shortens their life considerably. It is recommended therefore, that care be taken to compute the correct wattage for any given installation. Optimum wattage should result in a 50/50 off/on cycle. For very high temperature operation (over 750°F), off/on control might well be replaced by input voltage regulation through variable transformers or silicon rectifiers so that great temperature fluctuations in the heater wire are minimized.

Location of temperature control point

Precise control of your cartridge heater is important. Using a Thermocouple, RTD, or thermostat to sense temperature is key to success of process temperature. The sensing element ought not to be placed further than 1/2″ away from the heater wherever possible. Location further away could conceivably cause the unit to run too hot and thereby shorten life and increase process losses.

Wattage

Minimum wattage is based on 0 watts per square inch and up. Units with lower watt densities may be manufactured for special conditions such as high temperature or vibration. Minimum wattage available can be determined using hole fit formula calculations and working with our design engineers.

Cartridge Heater Applications:

- Dies and Molds

- Plastics Processing

- Manifolds

- Press Heating

- Seal Bars

- Hot Plates

- Packaging Equipment

- Liquid and Gas Heating

- Platen Heating

- Screen Changer