Home / Heaters / Cable Heaters / Coiled Cable

Coiled Cable – Phoenix Thermal Supply

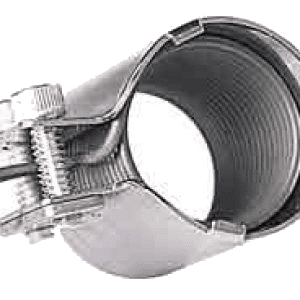

Axial Clamp Mini Coiled Nozzle Heaters

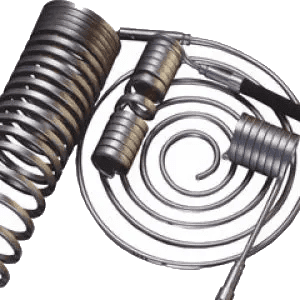

The versatile coiled cable heater can be formed to a variety of shapes. Cable heaters are small diameter, high performance units, fully annealed and readily bent to a multitude of configurations.

The coiled cable heater can be formed into a compact, coiled nozzle heater supplying a full 360º of heat with optional distributed wattage. A straight cable heater can snake through an equipment application. Flat spiral configurations can be used in high-tech manufacturing while a star wound cable can be used for air and gas heating.

Different applications where coiled cable heaters are used require different construction methods, including one, two or four resistance wires; parallel coil or straight wire; drawn or swaged sheaths; with or without internal thermocouples; leads exiting from one or both ends, and round, rectangular or square cable cross sectionals.

Whatever the application, the PTSHEAT coil and cable heater can be shaped to fit.

We look forward to working with you on your application. We can supply the same form, fit, and function heater to directly replace your OEM heater. We can also provide free part analysis to let you know why your heater has failed. Our engineers are factory trained to help you increase production and reduce down-time.

Coiled Cable Applications:

- Plastic processing machinery

- Hot runner mold

- Packaging machinery

- Dies & molds

- Shoe machinery

- Labeling machinery and a lot of other applications

- Food processing machinery

- Hot stamping

- Heating gases and liquids